Best quality Hho Oxy-Hydrogen Generator Car Engine Decarbonising Machine

Applied to hydrogenation machine and hydrogenation station

Best quality Hho Oxy-Hydrogen Generator Car Engine Decarbonising Machine

Product introduction

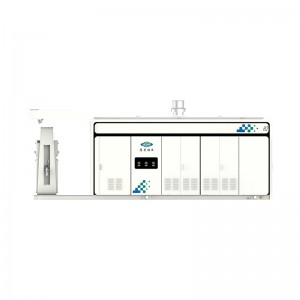

The compressor skid, which is the core of the hydrogen refueling station, is mainly composed of hydrogen compressor, pipeline system, cooling system, and electrical system. According to the type of compressor used, it can be divided into hydraulic pistoncompressor skid and diaphragm compressor skid.

According to the layout requirements of the hydrogen dispenser, it can be divided into the dispenser- on -the- skid type and not on the skid type. According to intended a application territory, it is divided into the GB Series and EN Series.

Product features

Anti-vibration and noise reduction: The system design adopts three measures of anti-vibration, vibration absorption, and isolation to reduce the noise of equipment.

Compressor skid

● Convenient maintenance: the skid includes multiple maintenance channels, membrane head maintenance beam hoisting tools, convenient equipment maintenance.

● The instrument is easy to observe: the observation area of the skid and instrument is located on the instrument panel, which is isolated from the process area, and can be used for safety precautions.

● Centralized collection of instruments and electrical: all instrument and electrical cables are integrated into the distributed collection cabinet, which reduces the amount of on-site installation and has a high degree of integration, and the starting method of the compressor is the soft start, which can be started and stopped locally and remotely.

● Anti-hydrogen accumulation: The anti-hydrogen accumulation structure design of the skid roof can prevent the possibility of hydrogen accumulation and ensure the safety of the skid.

● Automation: The skid has the functions of boosting, cooling, data acquisition, automatic control, safety monitoring, emergency stop, etc.

● Equipped with all-round safety components: the equipment includes a gas detector, flame detector, lighting, emergency stop button, local operation button interface, sound and light alarm, and other safety hardware facilities.

Specifications

Specifications

-

Inlet pressure

5MPa~20MPa

-

Filling capacity

50~1000kg/12h@12.5MPa

-

Outlet pressure

45MPa (for filling pressures not greater than 43.75MPa).

90MPa (for filling pressure not more than 87.5MPA). -

Ambient temperature

-25℃~55℃

“Quality 1st, Honesty as base, Sincere assistance and mutual profit” is our idea, in order to create consistently and pursue the excellence for Best quality Hho Oxy-Hydrogen Generator Car Engine Decarbonising Machine, We warmly welcome friends from all walks of life to seek mutual cooperation and create a more brilliant and splendid tomorrow.

“Quality 1st, Honesty as base, Sincere assistance and mutual profit” is our idea, in order to create consistently and pursue the excellence for China Hho Carbon Cleaning Machine and Fuel Injector Cleaning System, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to for you of fantastic good quality. Guided by the principle of “Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Application Scenario

Compressor skids are mainly used in hydrogen refueling stations or hydrogen mother stations, according to customer needs, different pressure levels, different skid type, and different application territories can be chosen, can be customized according to customer needs

“Quality 1st, Honesty as base, Sincere assistance and mutual profit” is our idea, in order to create consistently and pursue the excellence for Best quality Hho Oxy-Hydrogen Generator Car Engine Decarbonising Machine, We warmly welcome friends from all walks of life to seek mutual cooperation and create a more brilliant and splendid tomorrow.

Best quality China Hho Carbon Cleaning Machine and Fuel Injector Cleaning System, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to for you of fantastic good quality. Guided by the principle of “Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.