Containerized LNG Refueling station

Applied to hydrogenation machine and hydrogenation station

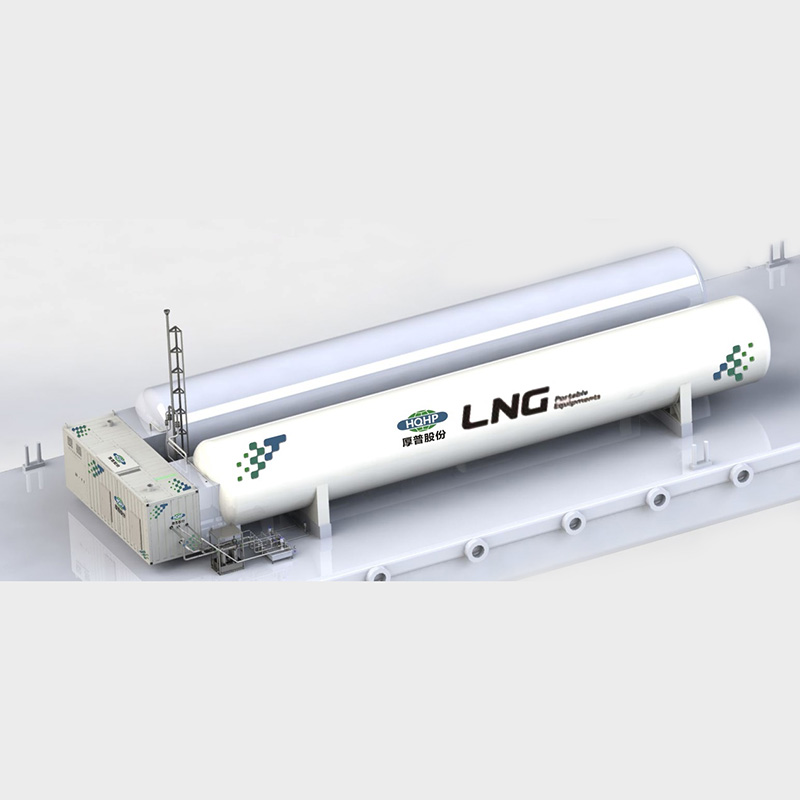

Containerized LNG Refueling station

Product introduction

HQHP containerized LNG refueling station adopts modular design, standardized management and intelligent production concept. At the same time, the product has the characteristics of beautiful appearance, stable performance, reliable quality and high refueling efficiency.

Compared with permanent LNG station, containerized type has advantages of smaller footprint, less civil work and easier to transport. It suits users with land constraints and want to put it into use as soon as possible.

The device is mainly composed of LNG dispenser, LNG vaporizer, LNG tank. The number of the dispenser, the size of tank and more detailed configurations could be customized accroding to needs.

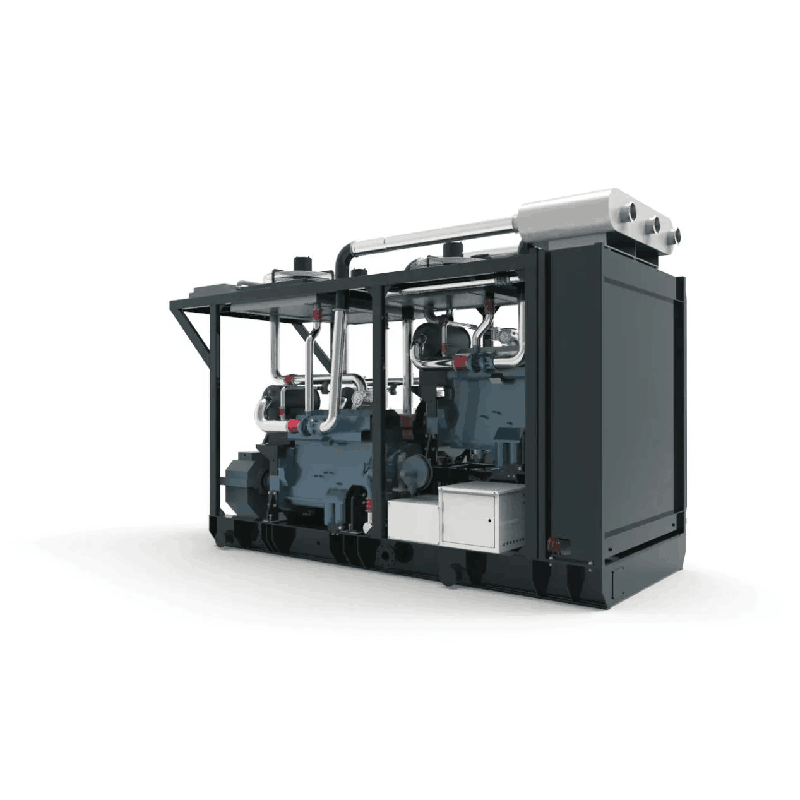

Products are mainly composed of standard containers, stainless steel metal cofferdams, vacuum storage tanks, submersible pumps, cryogenic vacuum pumps, vaporizers, cryogenic valves, pressure sensors, temperature sensors, gas probes, emergency stop buttons, dosing machines and pipeline systems.

Product features

Box structure, integrated storage tank, pump, dosing machine, overall transportation.

Containerized LNG filling device

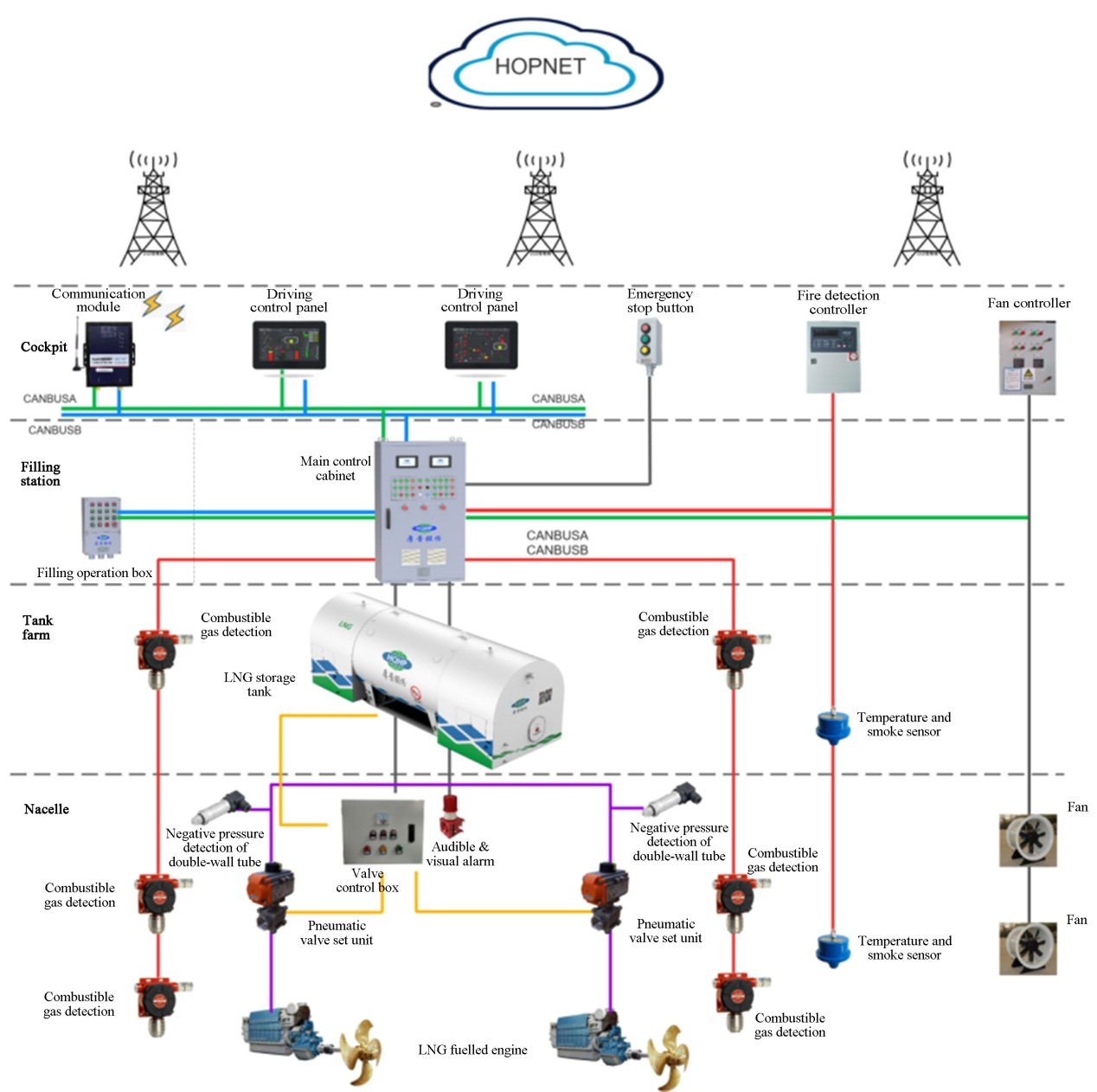

● Comprehensive security protection design, meet GB/CE standards.

● On-site installation is fast, fast commissioning, plug-and-play, ready to relocate.

● Perfect quality management system, reliable product quality, long service life.

● The use of double-layer stainless steel high vacuum pipeline, short pre-cooling time, fast filling speed.

● Standard 85L high vacuum pump pool, compatible with international mainstream brand submersible pump.

● Special frequency converter, automatic adjustment of filling pressure, saving energy and reducing carbon emissions.

● Equipped with independent pressurized carburetor and EAG vaporizer, high gasification efficiency.

● Configure special instrument panel installation pressure, liquid level, temperature and other instruments.

● The number of dosing machines can be set to multiple units (≤ 4 units).

● With LNG filling, unloading, pressure regulation, safe release and other functions.

● Liquid nitrogen cooling system (LIN) and in-line saturation system (SOF) are available.

● Standardized assembly line production mode, the annual output > 100 sets.

Specifications

|

Serial number |

Project |

Parameters/specifications |

|

1 |

Tank geometry |

60 m³ |

|

2 |

Single/double total power |

≤ 22 (44) kilowatts |

|

3 |

Design displacement |

≥ 20 (40) m3/h |

|

4 |

Power supply |

3P/400V/50HZ |

|

5 |

Net weight of the device |

35000~40000kg |

|

6 |

Working pressure/design pressure |

1.6/1.92 MPa |

|

7 |

Operating temperature/design temperature |

-162/-196°C |

|

8 |

Explosion-proof markings |

Ex d & ib mb II.A T4 Gb |

|

9 |

Size |

I:175000×3900×3900mm II: 13900×3900 ×3900 mm |

Application Scenarios

This product should be available for use in LNG filling stations with a daily LNG filling capacity of 50m3/d.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.