Cryogenic Storage Tanks And Ancillary Equipment

Applied to hydrogenation machine and hydrogenation station

Cryogenic Storage Tanks And Ancillary Equipment

Product introduction

The cryogenic liquid storage tank is a vertical or horizontal double-layer vacuum-insulated storage tank used to store liquid oxygen, nitrogen, argon, carbon dioxide, and other media.

Its main function is to fill and store cryogenic liquids.

Product Introduction

The cryogenic liquid storage tank is a vertical or horizontal double-layer vacuum-insulated storage tank used to store liquid oxygen, nitrogen, argon, carbon dioxide, and other media. Its main function is to fill and store cryogenic liquids. For the safe use requirements of cryogenic storage tanks, comprehensive consideration should be given to gas hazard characteristics, low-temperatures protection effect, surrounding environmental conditions, pressure vessel characteristics, etc., and corresponding technical management measures should be taken to ensure safe operation. Its normally include two categories in accordance with different thermal insulation modes: vacuum powder insulation and high-vacuum insulation. The cryogenic liquid storage tank has a double-layer structure, in which the inner casing is made of stainless steel and the outer casing is carbon steel. Two simplified bodies are filled with a heat insulating material to reduce the radiation heat transfer and the interlayer is under a vacuum state to reduce the heat transfer of the gas.

According to the medium installed in the low-temperature tank, it can be divided into a cryogenic LNG tank and an industrial storage tank.

Application Scenario

1. All LNG tanks have root valves with level gauges.

2. Industrial tanks (oxygen, nitrogen, argon): All liquid phase ports with double valves, gas phase ports with a single valve, lower self-pressurized vaporizer, and level gauge.

3. The material of the cylinder in the liquid carbon dioxide storage tank is 16MnDR, and the design pressure is 2.3 Mpa. All the liquid phase joints are equipped with double valves, gas phase joints are equipped with a single valve, without a lower self-pressurized vaporizer and the equipment is equipped with a liquid level meter.

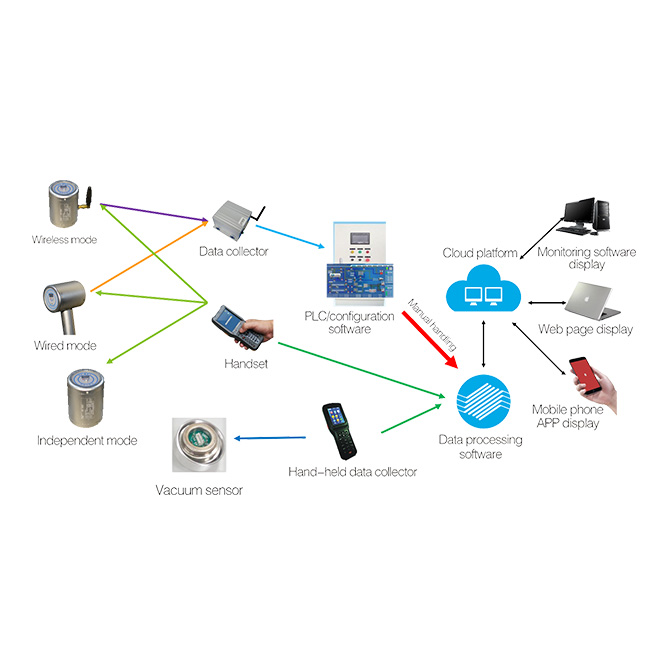

4. Able to detect vacuum degree online.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.