Good quality Lng Pipeline - Vertical/Horizontal LNG Cryogenic Storage Tank – HQHP

Good quality Lng Pipeline - Vertical/Horizontal LNG Cryogenic Storage Tank – HQHP

Product introduction

Specifications

Vertical tank

|

Specifications |

Geometric volume m3 |

Working pressure (Mpa) |

Dimensions (mm) |

Empty weight (kg) |

Remark |

|

CFL-9/0.8 |

10 |

0.8 |

φ 2016*7545 |

7900 |

3 supports |

|

CFL-9/1.05 |

10 |

1.05 |

8400 |

||

|

CFL-9/1.2 |

10 |

1.2 |

8400 |

||

|

CFL-18/0.8 |

20 |

0.8 |

φ 2500*8185 |

10000 |

3 supports |

|

CFL-18/1.05 |

20 |

1.05 |

11000 |

||

|

CFL-18/1.2 |

20 |

1.2 |

11000 |

||

|

CFL-27/0.8 |

30 |

0.8 |

|

13800 |

|

|

CFL-27/1.05 |

30 |

1.05 |

φ 2500*11575 |

15080 |

3 supports |

|

CFL-27/1.2 |

30 |

1.2 |

15080 |

||

|

CFL-45/0.8 |

50 |

0.8 |

φ3000 *11620 |

20400 |

3 supports |

|

CFL-45/1.05 |

50 |

1.05 |

23400 |

||

|

CFL-45/1.2 |

50 |

1.2 |

23400 |

||

|

CFL-54/0.8 |

60 |

0.8 |

φ3000 *13520 |

22500 |

3 supports |

|

CFL-54/1.05 |

60 |

1.05 |

25500 |

||

|

CFL-54/1.2 |

60 |

12 |

25500 |

||

|

CFL-90/0.8 |

100 |

0.8 |

φ3520 *16500 |

37200 |

4 supports |

|

CFL-135/0.8 |

150 |

0.8 |

φ3720 *21100 |

49710 |

4 supports |

Horizontal tank

|

Specifications |

Geometric volume m3 |

Working pressure (Mpa) |

Dimensions (mm) |

Empty weight (kg) |

Remark |

|

CFW-4.5/0.8 |

5 |

0.8 |

φ 2016*3960 |

5613 |

|

|

CFW-4.5/1.05 |

5 |

1.05 |

5913 |

|

|

|

CFW-4.5/1.2 |

5 |

1.2 |

5913 |

|

|

|

CFW-9/0.8 |

10 |

0.8 |

φ 2016*6676 |

7413 |

|

|

CFW-9/1.05 |

10 |

1.05 |

7915 |

|

|

|

CFW-9/1.2 |

10 |

1.2 |

7915 |

|

|

|

CFW-18/0.8 |

20 |

0.8 |

φ 2500*7368 |

10200 |

|

|

CFW-18/1.05 |

20 |

1.05 |

11300 |

|

|

|

CFW-18/1.2 |

20 |

1.2 |

11300 |

|

|

|

CFW-27/0.8 |

30 |

0.8 |

φ 2500*10016 |

12580 |

|

|

CFW-27/1.05 |

30 |

1.05 |

13880 |

|

|

|

CFW-27/1.2 |

30 |

1.2 |

13880 |

|

|

|

CFW-45/0.8 |

50 |

0.8 |

φ3000 *10750 |

18400 |

|

|

CFW-45/1.05 |

50 |

1.05 |

21000 |

|

|

|

CFW-45/1.2 |

50 |

1.2 |

21000 |

|

|

|

CFW-54/0.8 |

60 |

0.8 |

φ3000 *12650 |

20500 |

|

|

CFW-54/1.05 |

60 |

1.05 |

23500 |

|

|

|

CFW-54/1.2 |

60 |

1.2 |

23500 |

|

|

|

CFW-90/0.8 |

100 |

0.8 |

φ3520 *16500 |

35500 |

Application Scenario

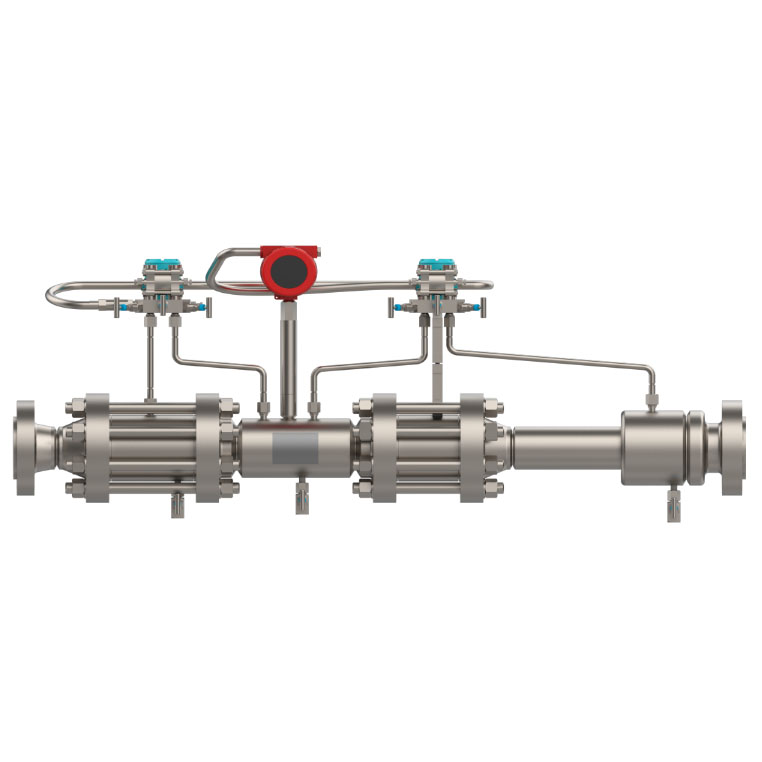

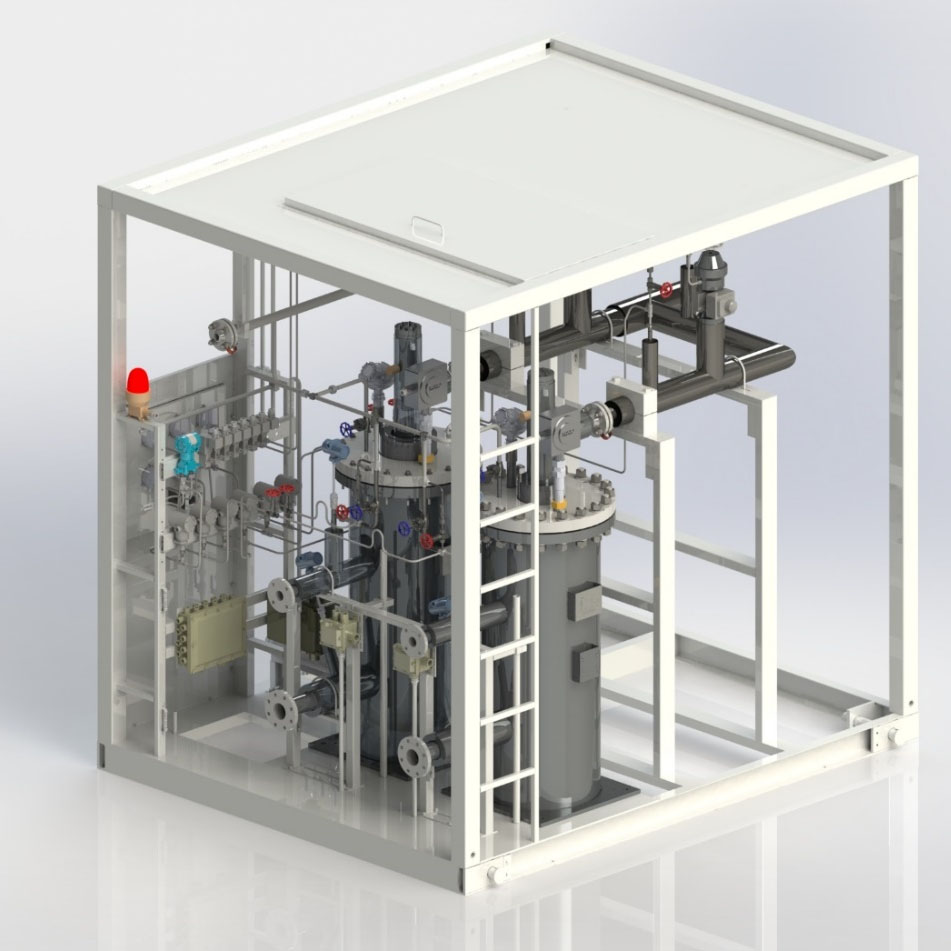

The LNG storage tank is composed of inner container, outer shell, support, process piping system, thermal insulation material and other components. The storage tank is a double-layer structure, the inner container is suspended inside the outer shell by means of a supporting device, and the interlayer space formed between the outer shell and the inner container is evacuated and filled with pearl sand for insulation (or high vacuum multi-layer insulation).

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.