HopNet Equipment Supervision System

Applied to hydrogenation machine and hydrogenation station

HopNet Equipment Supervision System

Product introduction

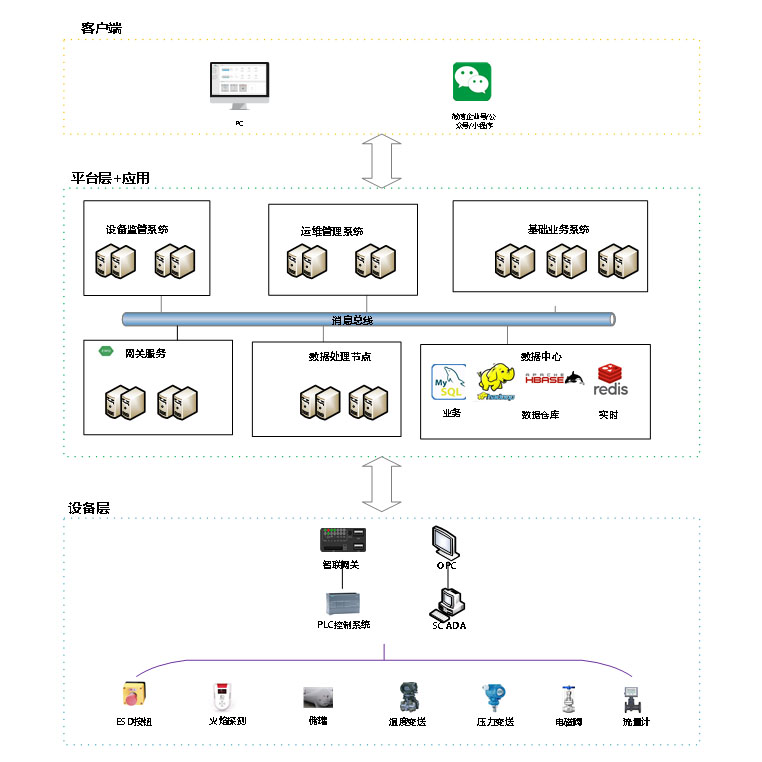

The Platform of Hopnet Equipment Supervision System uses Internet of things communication technology, big data analysis technology, remote monitoring, and analysis of special equipment data in the field of clean energy.

The platform can carry out dynamic safety supervision of equipment from multiple regions, multiple dimensions, and multiple scenarios, conduct a centralized and in-depth analysis of data for predictive maintenance and equipment safety pre-warning, and manage various data information of equipment in an orderly, dynamic and comprehensive manner like update and share, and ultimately achieve the purpose of improving the level of public safety management on site.

Product features

The platform realizes the collection and storage of multi-source heterogeneous data and real-time monitoring of the operation data of special equipment through data acquisition, screening, and eigenvalue extraction, analyze and deal with the risk factors of special equipment by building a specific scenario, a warning is issued as soon as a response scenario is triggered, so as to realize the management of equipment running state alarms and early warning. In short, the platform provides users with the following functions.

The platform of Hopnet Equipment Supervision System

● Real-time data monitoring: remotely monitor the operation status of the key equipment of the site in real-time through a mobile phone client or WEB system.

● Equipment operation and maintenance management: record the equipment inspection information and maintenance information through static and dynamic modes. When the equipment inspection expires or needs maintenance, the expired information will be pushed to customers in time to facilitate the arrangement of maintenance plans.

● Equipment alarm management: The platform performs hierarchical management of alarm information. Key alarm information needs to be handled by personnel and the processing results are uploaded to form closed-loop management.

● Query of equipment operation historical data: the platform provides reports or curves to query historical data, which is convenient for customers to conduct equipment operation and maintenance analysis.

● Visual LSD (large screen display): a personalized comprehensive operation and supervision LSD is developed according to the operation situation of the equipment at the customer site.

At the same time, the platform can also be adapted to various operating systems, not only the mainstream Windows and Linux systems, but also the Kunpeng system of Huawei.

Specifications

Specifications

-

Processing capacity

The platform has high data concurrency processing capability.

-

API

Can provide API interface for another system to access.

function

- If the customer adopts the deployment mode of our cloud platform, the visual LSD (large screen display) can be customized and developed.

- If the customer adopts privatized deployment, customized development can be carried out according to the customer's needs.

Application Scenarios

1. Monitor the operation of all site equipment through the visual LSD (large screen display) in the monitoring center of the customer's headquarters.

2. For the operation and maintenance personnel of the site, the storage tank inventory of the site can be monitored remotely to facilitate timely scheduling; It can receive the push of the expiration of supervision inspection and maintenance of key equipment in time, facilitating the timely formulation of equipment supervision inspection and maintenance work plan.

mission

Efficient use of energy to improve the human environment

Related products

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.