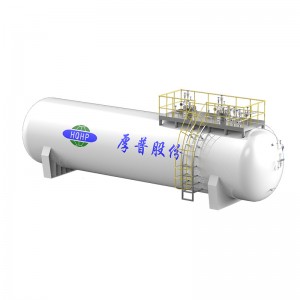

LNG Built-In Pump Filling equipment

Applied to hydrogenation machine and hydrogenation station

LNG Built-In Pump Filling equipment

Product introduction

The product is easy to operate and has obvious advantages when overhauling and draining and replacing the bottom valve.

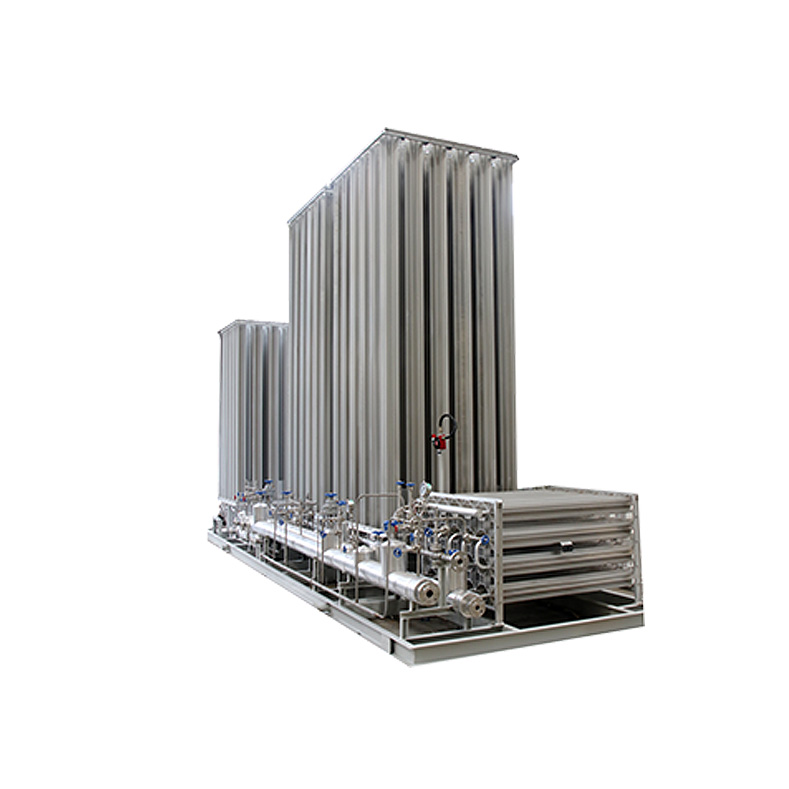

The built-in pump filling device is a set of integrated equipment designed according to CCS specifications, with a low-temperature submersible pump designed in the LNG storage tank, integrating storage and bunkering as a whole, with PLC control cabinet, power cabinet, the LNG bunkering control cabinet and LNG unloading skid can realize the functions of LNG trailer unloading, liquid storage, bunkering, etc, and have the characteristics of compact structure, short bunkering time and convenient maintenance.

Product features

Integrate storage and bunkering functions.

Built-in pump filling device

● Approved by CCS.

● The amount of BOG generated is less, and the operating loss is lower.

● Optimize the bunkering process, which can be filled in real time.

● The equipment is highly integrated and the installation space is small.

● Adopting special structure, it is convenient to overhaul the pump and bottom valve.

● Can be customized according to user needs.

Specifications

| Model |

HPQF series |

||||

| Dimension(L×W×H) | 1300×3000×5000 (mm) | 1400×3900×5300 (mm) | 1500×5700×6700 (mm) | 2400×5200×6400 (mm) | 2200×5300×7100 (mm) |

| Geometric capacity | 60m³ | 100 m³ | 200m³ | 250m³ | 300m³ |

| Flowrate | 60 m³/h | ||||

| Head | 220m | ||||

| Tank working pressure | ≤1.0MPa | ||||

Application

This product is suitable for on-water LNG bunkering stations built on barge or LNG fuel-powered ships with limited installation space.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.