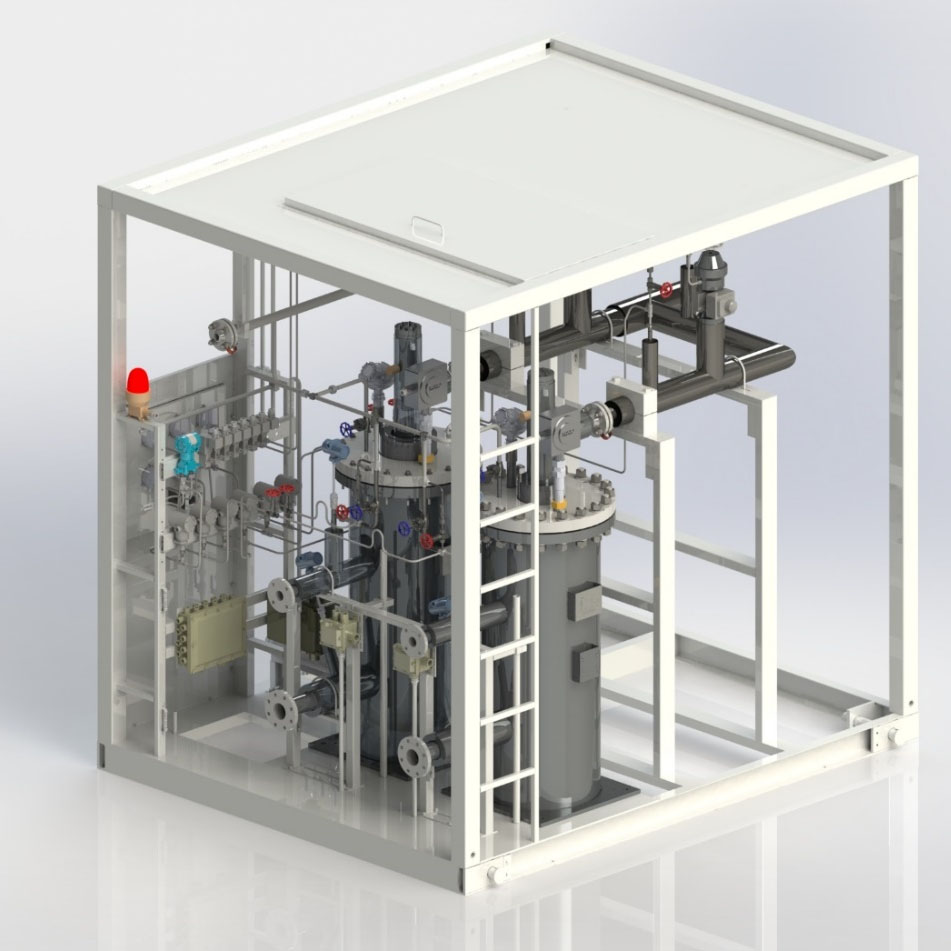

LNG Shore-Based Refueling Skid

Applied to hydrogenation machine and hydrogenation station

LNG Shore-Based Refueling Skid

Product introduction

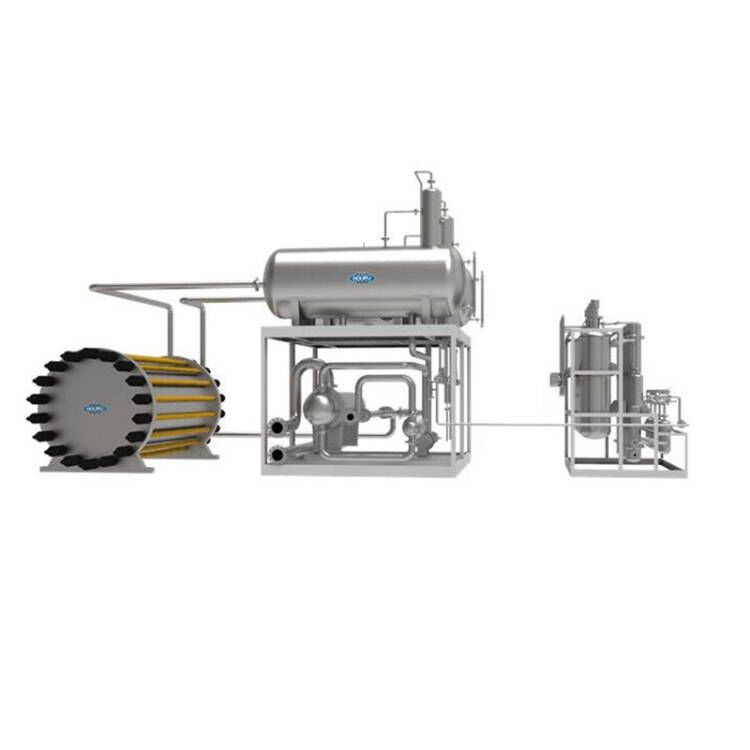

The shore-based filling skid is the core equipment of the shore-based LNG bunkering station.

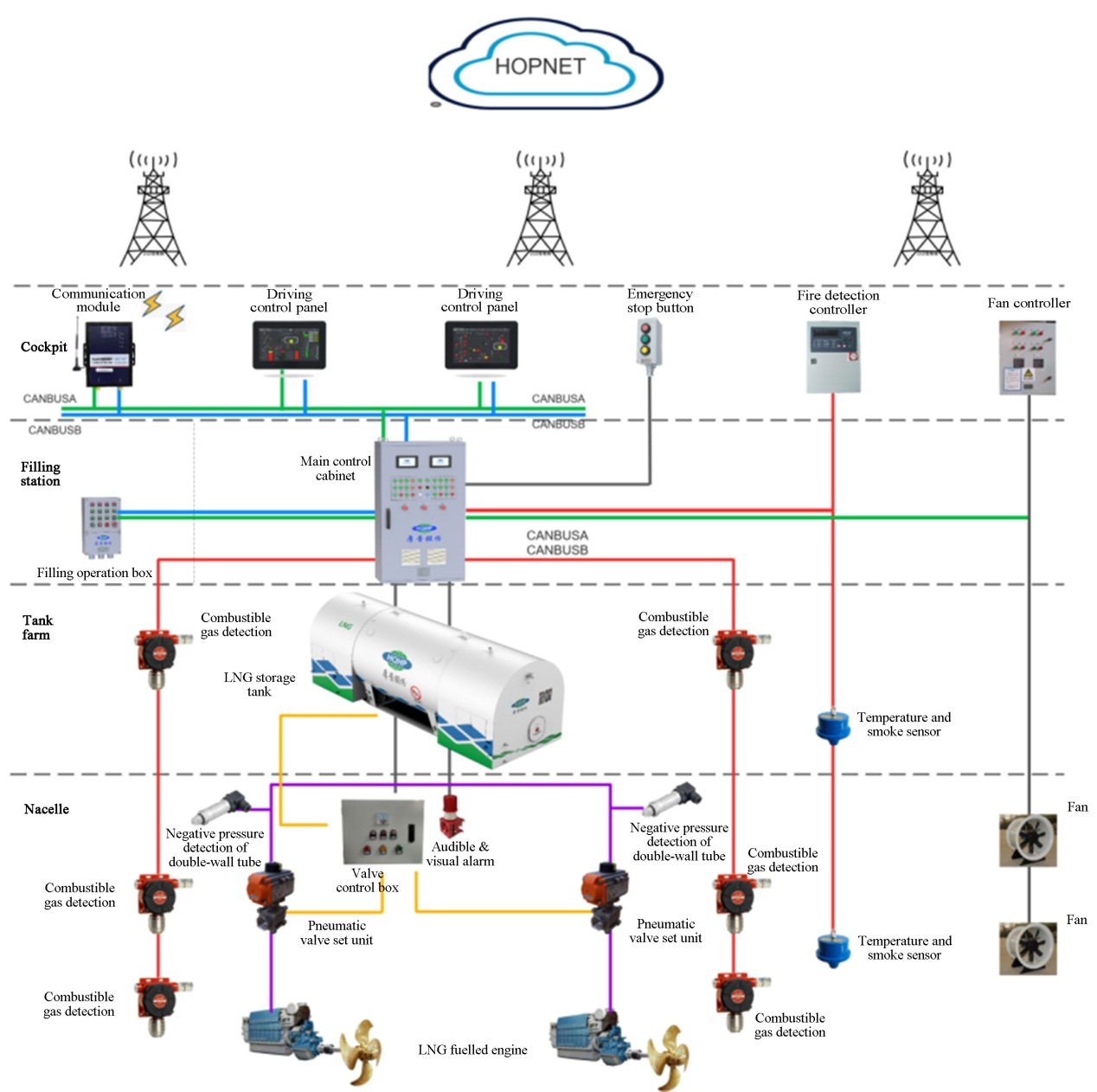

It integrates the functions of filling and pre-cooling, and can realize the bunkering function with the PLC control cabinet, power drag cabinet and liquid filling control cabinet, the maximum filling volume can reach 54 m³/h. At the same time, according to customer needs, the LNG trailer unloading, storage tank pressurization and other functions can be added.

Product features

Highly integrated design, small footprint, less on-site installation workload, and fast commissioning.

Shore-Based Filling Skid

● Skid-mounted design, easy to transport and transfer, with good mobility.

● Can be adapted to different types of tanks, with strong versatility.

● Large filling flow and fast filling speed.

● All electrical instruments and explosion-proof boxes in the skid are grounded in accordance with the requirements of the national standard, and the electrical control cabinet is independently installed in a safe area, reducing the use of explosion-proof electrical components and making the system safer.

● Integrated with PLC automatic control system, HMI interface and convenient operation.

● Can be customized according to user needs.

Specifications

| Product number | HPQF series | Design Tempreture | -196~55 ℃ |

| Product Size (L×W×H) | 3000×2438×2900 (mm) | Total Power | ≤70KW |

| Product Weight | 3500kg | Electric System | AC380V, AC220V, DC24V |

| Fill Amount | ≤54m³/h | Noise | ≤55dB |

| Applicable Media | LNG/liquid nitrogen | Trouble Free Working Time | ³5000h |

| Design Pressure | 1.6MPa | Measurement Error | ≤1.0% |

| Work Pressure | ≤1.2MPa | -- | -- |

Application

This product is used as the filling module of the shore-based LNG Bunkering station and is only used for the shore-based filling system.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.