Non Basic Compressor

Non Basic Compressor

Product introduction

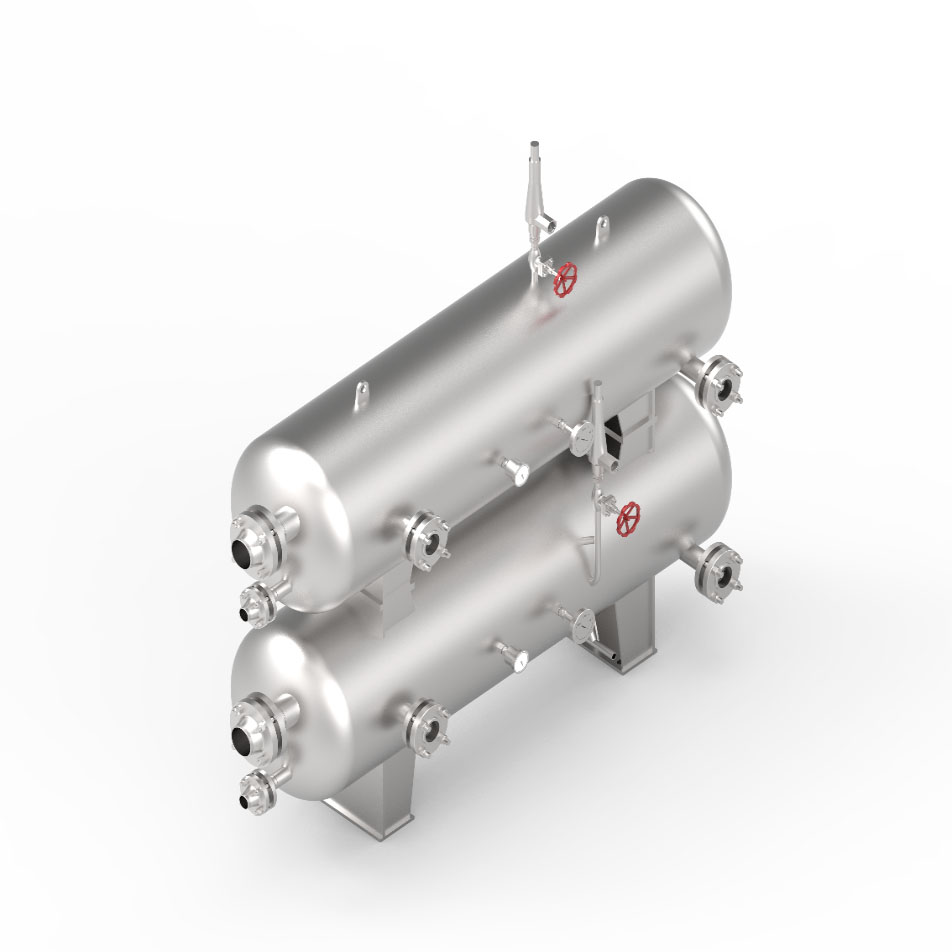

Non basic compressors: Non basic compressors are selected based on different scenarios of customer needs, such as frequent equipment relocation or in vehicle compressors being the optimal choice; Its advantage is that the equipment is installed quickly and can be put into operation quickly after arriving on site, saving the installation process and waiting time for secondary grouting. Currently, it is widely used in oil and gas fields;

Product introduction

Non basic compressors: Non basic compressors are selected based on different scenarios of customer needs, such as frequent equipment relocation or in vehicle compressors being the optimal choice; Its advantage is that the equipment is installed quickly and can be put into operation quickly after arriving on site, saving the installation process and waiting time for secondary grouting. Currently, it is widely used in oil and gas fields;

Advantages of control cabinet prying: Control cabinet prying is currently a widely used process in oil and gas fields. This process mainly saves on-site installation time, enables rapid production, saves long-distance cable and construction costs, and 1s relatively widely used in oil and gas fields and refueling stations;

Comparison between variable frequency and soft start: The motor starter is an important choice for equipment selection. Soft start has a significant impact on the power grid during compressor startup, and transformer selection should be based on 3-4 times the rated power of the main motor of the equipment. Its price is relatively cheap compared to that of frequency converters. The frequency converter has less impact on the power grid when starting the compressor. The selection of transformer should be based on 1.5 times the rated power of the main motor of the equipment The frequency converter can also operate the compressor under variable operating cond 巾 ons, maximizing the utilization of the compressor, and its price is higher than that of soft start,

Specifications

|

model |

2D |

|

Lubrication method for moving parts |

Pressure lubrication |

|

speed |

740-1200rpm |

|

Cylinder lubrication method |

Low oil/no oil |

|

Cylinder cooling method |

Water cooling/mixed cooling/air cooling |

|

Piston rod diameter |

50mm/60mm |

|

stroke |

120mm |

|

Maximum shaft power |

740kw |

| model | 4M |

| Lubrication method for moving parts | Pressure lubrication |

| speed | 740-1200rpm |

| Cylinder lubrication method | Low oil/no oil |

| Cylinder cooling method | Water cooling/mixed cooling/air cooling |

| Piston rod diameter | 50mm/60mm |

| stroke | 120mm |

| Maximum shaft power | 1500kw |

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.