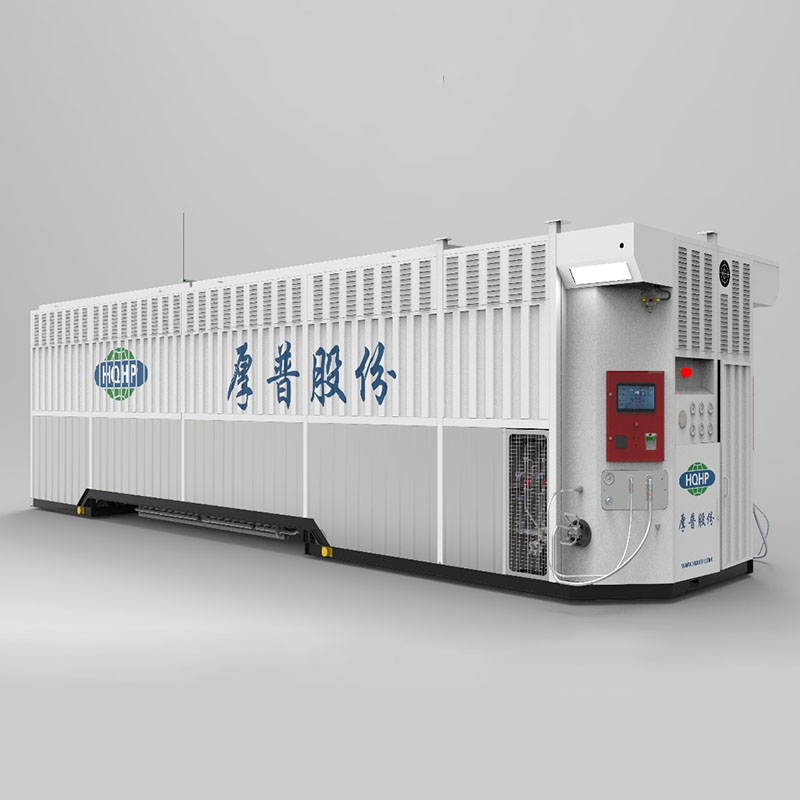

Unmanned Containerized LNG Refueling Station

Applied to hydrogenation machine and hydrogenation station

Unmanned Containerized LNG Refueling Station

Product introduction

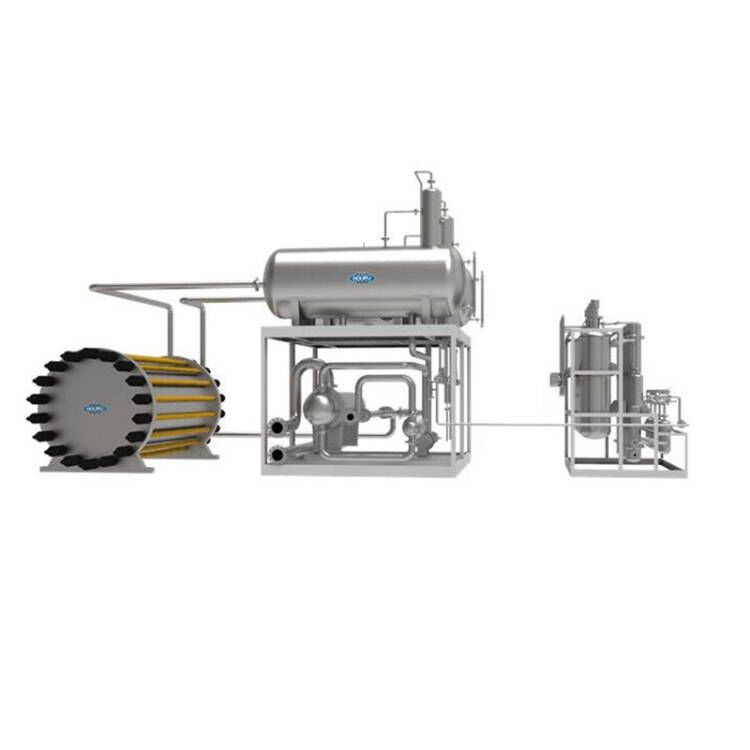

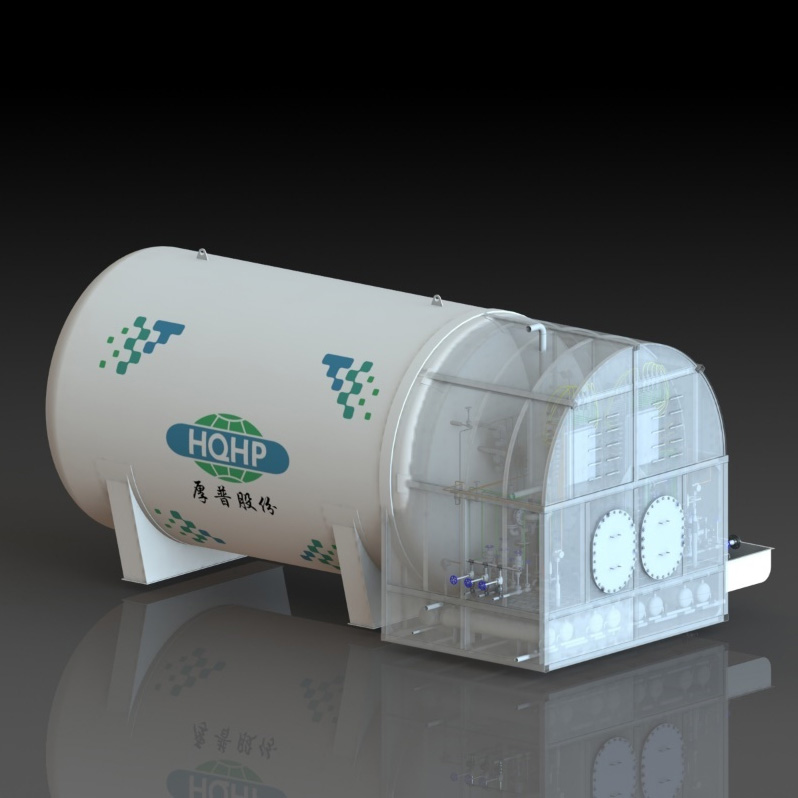

The containerized filling skid is an equipment combination that integrates LNG storage tanks, cryogenic submersible pumps, vaporizers, liquid filling control cabinets and other equipment in a containerized skid body (with a metal bound wall).

It can realize the functions of LNG trailer unloading, LNG storage, filling, metering, safety alarm and other functions.

Product features

The linkage function of grounding alarm and filling, when the grounding is poor, the system will give an alarm to prevent the filling.

Containerized filling Skid

● The equipment is integrated as a whole, which can be transported and hoisted as a whole, and there is no welding work on site.

● The equipment as a whole has explosion-proof certification and safety assessment certificate.

● The amount of BOG produced is small, the filling speed is fast, and the liquid filling flow is large.

● The comprehensive cost of building the station is the lowest, the on-site civil construction is less, and the foundation is simple; there is no process pipeline installation.

● The whole is easy to maintain and manage, flexible to move, and easy to move and relocate as a whole.

Specifications

| Product number | H PQL series | Work pressure | ≤1.2MPa |

| Tank volume | 60 m³ | Set tempreture | -196 ~ 55 ℃ |

| Product size (L× W × H) | 15400×3900×3900 (mm) | Total power | ≤30kW |

| Product weight | 40T | Electric system | AC380V, AC220V, DC24V |

| Injection flow | ≤30m³/h | Noise | ≤55dB |

| Applicable media | LNG / Liquid Nitrogen | Trouble free working time | ≥5000h |

| Design pressure | 1.6MPa | Gas filling system metering error | ≤1.0% |

Application

This equipment is mainly suitable for small shore-based LNG filling systems with small installation area and certain transshipment requirements.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.