Unmanned Containerized LNG Refueling station

Applied to hydrogenation machine and hydrogenation station

Unmanned Containerized LNG Refueling station

Product introduction

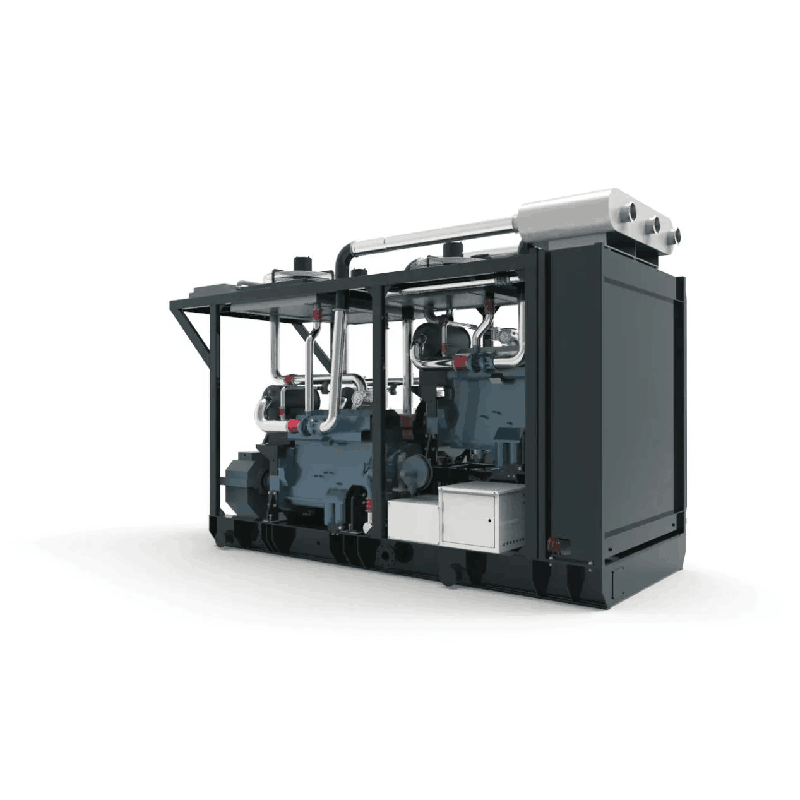

The unmanned containerized LNG refueling station could realize 24/7 accessibility automated refueling of NGV (Natural Gas Vehicle), remote monitoring and control, remote fault detect, and automatic trade settlement. It composed of LNG dispensers, LNG storage tanks, LNG vaporizers, safety system and etc,. Partial configurations could be adjusted according to customer requirements.

HOUPU unmanned containerized LNG refueling device adopts modular design, standardized management and intelligent production concept. At the same time, the product has the characteristics of beautiful appearance, stable performance, reliable quality, high refueling efficiency, and it has wide range of application cases.

The products are mainly composed of fire control room, vacuum storage tank, cryogenic vacuum pump, vaporizer, cryogenic valve, pressure sensor, temperature sensor, gas probe, emergency stop button, dosing machine and pipeline system.

Product features

On-site installation is fast, fast commissioning, plug-and-play, ready to relocate.

Unattended container LNG filling equipment

● Standard 45-foot containerized construction with integrated storage tanks, pumps, dosing machines, and integral transportation.

● With LNG filling, unloading, pressure regulation, safe release and other functions.

● Perfect quality management system, reliable product quality, long service life.

● Unattended integrated control system, independent BPCS and SIS.

● Integrated video surveillance system (CCTV) with SMS reminder function.

● Special frequency converter, automatic adjustment of filling pressure, energy saving, reduce carbon emissions.

● The use of double-layer stainless steel high vacuum pipeline, short pre-cooling time, fast filling speed.

● Standard 85L high vacuum pump pool volume, compatible with international mainstream brand submersible pump.

● Equipped with independent pressurized carburetor and EAG vaporizer, high gasification efficiency.

● Configure special instrument panel installation pressure, liquid level, temperature and other instruments.

● Liquid nitrogen cooling system (LIN) and in-line saturation system (SOF) are available.

● Standardized assembly line production mode, the annual output > 100 sets.

● Meet CE requirements, has obtained ATEX, MD, PED, MID and other certifications.

Specifications

|

Serial number |

Project |

Parameters/specifications |

|

1 |

Tank volume |

30 cubic meters |

|

2 |

Total power |

≤ 22 kW |

|

3 |

Design displacement |

≥ 20 m 3/h |

|

4 |

Power supply |

3P/400V/50HZ |

|

5 |

Net weight of the device |

22000 kg |

|

6 |

Working pressure/design pressure |

1.6/1.92 MPa |

|

7 |

Operating temperature/design temperature |

-162/-196°C |

|

8 |

Explosion-proof markings |

Ex d e ib mb II.B T4 Gb |

|

9 |

Size |

13716×2438 ×2896 mm |

Application Scenarios

This product is used in unattended LNG filling station, LNG daily filling capacity of 30m3/d.

mission

Efficient use of energy to improve the human environment

contact us

Since its establishment, our factory has been developing first world class products with adhering the principle of quality first. Our products have gained excellent reputation in the industry and valuable trust among new and old customers.